Καλύτερης ποιότητας χρωματισμός χύτευσης χύτευσης χύτευσης χύτευσης χύτευσης χύτευσης χύτευσης χάλυβα

ΠαραγωγήΠεριγραφή του προϊόντος:

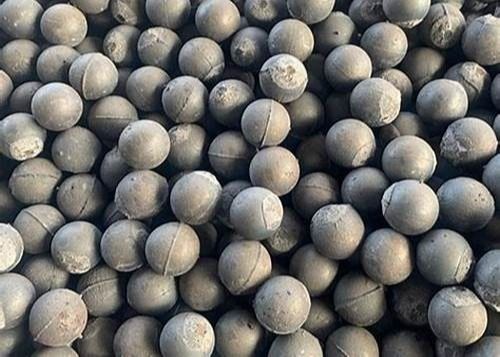

Οι σφαίρες χύτευσης από χάλυβα παράγονται με τήξη των αποβλήτων χάλυβα, των αποβλήτων σιδήρου και άλλων υλικών απορριμμάτων από φούρνους με τη χρήση ηλεκτρικού φούρνου μεσαίας συχνότητας,και προσθέτοντας κατάλληλη ποσότητα κράματος πολύτιμων μετάλλων (όπως σιδηροχρώμιο), σιδηρομαγγανίου, σιδηροβανανδίου κ.λπ.) κατά τη διάρκεια της διαδικασίας τήξης για την εξασθένηση και την καύση της χημικής σύνθεσης.Όταν η θερμοκρασία του λιωμένου σιδήρου υπερβαίνει τους 1550 °C και πληροί τις απαιτήσεις της διαδικασίας, το ειδικό λιωμένο σίδηρο χύνεται στο καλούπι σιδηροπλαστικής σφαίρας και το σφαιρικό ανθεκτικό στην φθορά σώμα σιδηροσμείγματος κατασκευάζεται μέσω διαδικασιών θέρμανσης, θέρμανσης, δοκιμής και συσκευασίας.

1.Εξοπλισμός: Το προϊόν είναι μια ανθεκτική στην φθορά σφαίρα από χάλυβα από σφυρηλατημένο υλικό με μεγάλη διάμετρο. Έχει σχεδιαστεί ειδικά για εφαρμογές σφυρίσματος.

2.Διάμετρος προσαρμογής: Το προϊόν κατασκευάζεται για να ανταποκρίνεται στις ειδικές απαιτήσεις διαμέτρου των πελατών, που κυμαίνονται από 20-150 mm.

3Σκληρωμένος χάλυβας: Ο κραματοποιημένος χάλυβας που χρησιμοποιείται για την παραγωγή εξασφαλίζει ότι η σφαίρα έχει τιμή σκληρότητας μεγαλύτερη από 60HRC, γεγονός που ενισχύει την αντοχή και την αντοχή σε κρούσεις.

4Διαφορετικά υλικά: Το προϊόν είναι κατασκευασμένο από διάφορα υλικά, συμπεριλαμβανομένου του χάλυβα, του χάλυβα άνθρακα, του υψηλού χρωμίου, του χαμηλού χρωμίου, του B2B3 45#,παρέχοντας ευελιξία και ποικίλες λειτουργίες για την κάλυψη ποικίλων αναγκών βιομηχανικών εφαρμογών.

5Πιστοποιητικά δοκιμών: Οι πελάτες μπορούν να αναμένουν να λαμβάνουν λεπτομερή βίντεο ελέγχου και εκθέσεις δοκιμών μηχανών για κάθε παρτίδα προϊόντος που αγοράζουν.Οι εκθέσεις αυτές παρέχουν ολοκληρωμένη ανάλυση των υλικών, επεξεργασία και απόδοση του προϊόντος.

Τεχνικές παραμέτρους:

| Ονομασία του προϊόντος |

Υψηλής αντοχής σε πρόσκρουση και φθορά χυτοσίδηρες σφαίρες υψηλής ποιότητας |

| Κατηγορία προϊόντων |

Σφαίρες από χυτοσίδηρο |

| Πλεονεκτήματα |

Όλα τα υλικά άλεσης μπορούν να κάνουν το γνωστό και πιο επαγγελματικό στην βιομηχανία δοκιμών μέσων άλεσης Πιστοποιητικό: ISO, δική παραγωγή, χωρίς άλλα έξοδα προμήθειας,Παροχή εγκαίρως λόγω της παραγωγικής ικανότητας: 100.000 τόνους/έτος |

| Χαρακτηριστικά |

Υψηλή σκληρότητα, εξαιρετική αντοχή στην φθορά, αδιάσπαστη φύση, υψηλή αξία κρούσης |

| Πιστοποιητικό |

ISO9001-2008, SGS |

| Σκληρότητα |

HRC 60-66 |

| Τοποθεσία |

Zhangqiu, πόλη Jinan, επαρχία Shandong, Κίνα |

| Εργατικό δυναμικό |

150 αφοσιωμένοι εργαζόμενοι, μεταξύ των οποίων 21 τεχνικοί υψηλής εξειδίκευσης |

| Εφαρμοσμένα πεδία |

Ορυχεία, εργοστάσια τσιμέντου, σταθμοί ηλεκτροπαραγωγής, χημική βιομηχανία |

| Χρόνος παράδοσης |

1-3 εβδομάδες μετά την προκαταβολή |

Εφαρμογές:

Οι σφαίρες από χυτοσίδηρο ZW είναι ευέλικτες και ανθεκτικές, καθιστώντας τις κατάλληλες για ένα ευρύ φάσμα περιπτώσεων και σενάριων εφαρμογής προϊόντων.και ειδικό, αυτές οι μπάλες είναι ιδανικές για διαφορετικές ανάγκες άλεσης.

Αυτές οι μπάλες χυτοσίδερου είναι πιστοποιημένες με ISO9001:2008Προερχόμενες από την πόλη Jinan, επαρχία Shandong, Κίνα, αυτές οι μπάλες έχουν ελάχιστη ποσότητα παραγγελίας 25 τόνων,και η τιμή είναι διαπραγματεύσιμη με βάση τον όγκο της παραγγελίας.

Οι όροι πληρωμής για αυτές τις μπάλες περιλαμβάνουν T/T ή LC κατά την προβολή, παρέχοντας ευελιξία στους αγοραστές.Οι πελάτες μπορούν να βασίζονται σε μια σταθερή πηγή αυτών των σκληρυμένων σιδερένιων σφαιρών..

Οι χρόνοι παράδοσης των σφαιρών χυτοσίδηρου ZW είναι γρήγοροι, μεταξύ 1-3 εβδομάδων μετά την προκαταβολή.διασφάλιση της ασφαλούς και αποτελεσματικής μεταφοράς των σφαιρών.

Με εύρος σκληρότητας HRC 60-66, αυτές οι ανθεκτικές στην τριβή σιδερένια σφαίρες έχουν σχεδιαστεί για να αντέχουν σε υψηλές συγκρούσεις και να παρέχουν αποτελεσματικές επιδόσεις άλεσης.Η κατηγορία προϊόντων των σφαιρών χυτοσίδηρου προσφέρει ένα ευρύ φάσμα εφαρμογών σε διάφορες βιομηχανίες.

Τα πλεονεκτήματα της επιλογής των σφαιρών χυτοσίδηρου ZW περιλαμβάνουν την ικανότητά τους να αποδίδουν καλά στις δοκιμές της βιομηχανίας συσσωρευτικών μέσων, με όλα τα υλικά σφυρίσματος να πληρούν τα επαγγελματικά πρότυπα.οι μπάλες έχουν πιστοποίηση ISO και παράγονται εσωτερικά, με εξάλειψη των πρόσθετων εξόδων προμήθειας.

Με παραγωγική ικανότητα 100.000 τόνων ετησίως, οι πελάτες μπορούν να βασίζονται σε έγκαιρες παραδόσεις αυτών των σφαιρών χυτοσίδηρου.Οι επιλογές συσκευασίας από χάλυβα (850 kg ανά τύμπανο) ή ευέλικτες σακούλες εμπορευματοκιβωτίων (1000 kg ανά σακούλα) παρέχουν βολικές επιλογές για διαφορετικές ανάγκες μεταφοράς.

Συνολικά, οι σφαίρες χυτοσίδηρου ZW αποτελούν αξιόπιστη και υψηλής ποιότητας επιλογή για τους πελάτες που αναζητούν ανθεκτικά και αποτελεσματικά μέσα άλεσης για διάφορες βιομηχανικές εφαρμογές.

Πληροφορίες εταιρείας:

Η Jinan Zhongwei ιδρύθηκε το 2000, είμαστε ένας κορυφαίος κατασκευαστής και επαγγελματίας εξαγωγέας σφαιρών άλεσης στην Κίνα.

Η εταιρεία μας καλύπτει έκταση 15000 τετραγωνικών μέτρων, τώρα έχουμε 150 υπαλλήλους, συμπεριλαμβανομένων 13 τεχνικών υπαλλήλων. Η ετήσια παραγωγή είναι 50000 τόνους έως 80000 τόνους.

Κύρια προϊόντα: σφυρηλατημένες σφαιρίδες από χάλυβα, σφαιρίδες από χυτοσίδηρο, άξονες άλεσης, κυλίνδρες

Έχουμε εξαγάγει σε περισσότερες από 20 χώρες, ΗΑΕ, Ζάμπια, Νότια Αφρική, Περού, Χιλή, Αυστραλία, Ηνωμένο Βασίλειο, ΗΠΑ, Τουρκία και ούτω καθεξής.

Υποστήριξη και υπηρεσίες:

Η ομάδα τεχνικής υποστήριξης και εξυπηρέτησης προϊόντων μας είναι αφιερωμένη στο να σας βοηθήσει με οποιαδήποτε ερώτηση που σχετίζεται με το προϊόν μας.ή βοήθεια επίλυσης προβλημάτωνΟι ειδικοί μας είναι εδώ για να σας υποστηρίξουν σε κάθε βήμα.

Συσκευή και αποστολή:

Συσκευασία προϊόντων για σφαίρες χυτοσίδηρου:

Κάθε σετ από χυτοσίδηρες σφαίρες συσκευάζεται προσεκτικά σε ένα ανθεκτικό κουτί για να εξασφαλιστεί η ασφαλή παράδοση.

Πληροφορίες αποστολής:

Προσφέρουμε τυποποιημένη αποστολή για το προϊόν Σφαιρίδια Χαλυβουργού. Οι παραγγελίες συνήθως επεξεργάζονται και αποστέλλονται εντός 1-2 εργάσιμων ημερών. Οι χρόνοι αποστολής μπορεί να διαφέρουν ανάλογα με την τοποθεσία σας.

Δοκιμές

Ελέγχος ποιότητας για κάθε βάρδια παραγωγής (4 ώρες/βάρδια) ·

Διάκριση της σκληρότητας, των χημικών στοιχείων και των δοκιμών αντίκτυπου μετά την παραγωγή για κάθε βάρδια παραγωγής·

Ελέγχος από τρίτο μέρος πριν από κάθε παράδοση

Η διαδικασία ελέγχου ποιότητας σιδηρουργικών σφαιρών περιλαμβάνει κυρίως τα ακόλουθα στάδια:Ελέγξτε την ποιότητα της επιφάνειας της χάλυβα για να παρατηρήσετε αν υπάρχουν προφανή ελαττώματα όπως ρωγμές, καταδυνάμωση, φυσαλίδες κλπ. Αυτά τα ελαττώματα θα επηρεάσουν τις επιδόσεις και τη διάρκεια ζωής της σφαίρας χάλυβα.

Ανίχνευση μεγέθους και βάρους: Χρησιμοποιήστε ακριβή όργανα μέτρησης, όπως σφραγίδες και μικρομέτρα, για τη μέτρηση της διάμετρος, της στρογγυλότητας,το βάρος και άλλους δείκτες της σφαίρας από χάλυβα και τις συγκρίνουν με τις τυποποιημένες τιμέςΕάν υπάρχει μεγάλη απόκλιση, αυτό σημαίνει ότι υπάρχει πρόβλημα με το μέγεθος και το βάρος της σφαίρας χάλυβα.

Δοκιμή σκληρότητας: Χρησιμοποιήστε δοκιμαστή σκληρότητας για να μετρήσετε την τιμή σκληρότητας της σφαίρας χάλυβα για να προσδιορίσετε εάν πληροί τις προδιαγραφές του προτύπου.Η τιμή σκληρότητας σχετίζεται με παράγοντες όπως η χημική σύνθεση και η διαδικασία θερμικής επεξεργασίας.

Ανάλυση χημικής σύνθεσης: Use modern equipment such as inductively coupled plasma optical emission spectrometer (ICP-OES) to analyze the chemical composition of the steel ball to ensure that its composition meets the prescribed chemical composition standards.

Μεταλλουργική ανάλυση δομής: Χρησιμοποιήστε οπτικά μικροσκόπια και άλλο εξοπλισμό για να παρατηρήσετε τη μεταλλωγραφική δομή της σφαίρας χάλυβα, να αξιολογήσετε την οργανωτική μορφολογία της, το μέγεθος του κόκκου,κατανομή φάσης, κλπ., για να κατανοήσουμε τις μηχανικές του ιδιότητες και την αντοχή στην φθορά.

Δοκιμή φυσικών ιδιοτήτων: περιλαμβάνονται δοκιμές εφελκυσμού και κάμψης για την αξιολόγηση της συμμόρφωσης των φυσικών ιδιοτήτων της σφαίρας χάλυβα με τις απαιτήσεις.μηχανικές ιδιότητες και χαρακτηριστικά δονήσεων της σφαίρας από χάλυβα.

Δοκιμή αντοχής στην φθορά: Δοκιμάστε την αντοχή στην φθορά της σφαίρας χάλυβα υπό πραγματικές συνθήκες χρήσης για να εξασφαλιστεί η απόδοσή της σε μακροχρόνια χρήση.

Δοκιμή κόπωσης: Αξιολογείται η διάρκεια ζωής της σφαίρας από χάλυβα υπό επαναλαμβανόμενες συνθήκες άγχους, ώστε να εξασφαλίζεται η σταθερότητά της υπό υψηλό φορτίο.

Πιστοποιητικό

ISO9001-2008, SGS

Το πλεονέκτημα μας:

1. Όλα τα υλικά άλεσης μπορεί να κάνει το γνωστό και πιο επαγγελματικό στην βιομηχανία δοκιμής πιστοποιητικό μέσων άλεσης: ISO

2Όλα τα προϊόντα είναι δική μας παραγωγή, χωρίς άλλα έξοδα επιτροπής.

3- Παροχή εγκαίρως, λόγω της παραγωγικής μας ικανότητας: 100.000 τόνους/έτος

Γενικά ερωτήματα:

Ε. Ποια είναι τα πλεονεκτήματα της εταιρείας σας;Η εταιρεία μας έχει μια επαγγελματική ομάδα και μια επαγγελματική γραμμή παραγωγής.

Ε. Γιατί να επιλέξω το προϊόν σας;

Α2. Τα προϊόντα μας είναι υψηλής ποιότητας και χαμηλής τιμής.

Ε3.Υπάρχει κάποια άλλη καλή υπηρεσία που μπορεί να προσφέρει η εταιρεία σας;

Α3. Ναι, μπορούμε να παρέχουμε καλή υπηρεσία μετά την πώληση και γρήγορη παράδοση.

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!  Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!